Discover how AI-Enhanced Production in Sustainable Manufacturing is revolutionizing factories with intelligent automation, predictive analytics, waste reduction, and eco-friendly operations for a future-ready industrial ecosystem.

Introduction

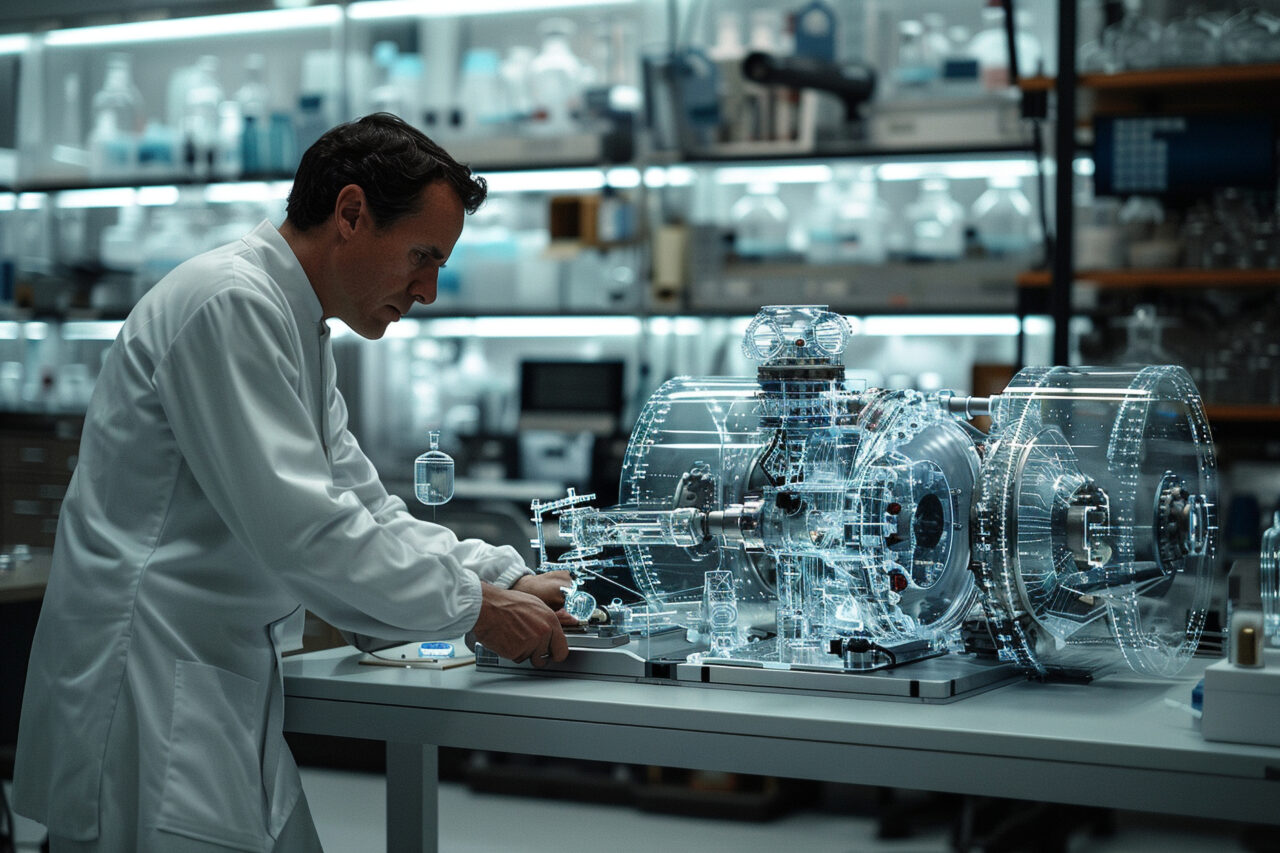

The world of manufacturing is undergoing a profound transition. With rising climate concerns, stricter environmental policies, and growing consumer expectations for eco-friendly products, sustainable practices are no longer optional they are essential. This shift is powered by a new industrial paradigm: AI-Enhanced Production in Sustainable Manufacturing. It enables factories to adapt in real time, optimize resources, reduce waste, and operate with a fluid efficiency that traditional production systems could never achieve.

This transformation is what we call fluid fabrication a future where intelligence, automation, and sustainability flow together seamlessly.

What Makes Manufacturing “Fluid”?

Traditional manufacturing is built on rigid workflows. The moment something changes a supplier delay, machine fault, or sudden demand fluctuation performance drops, waste rises, and energy consumption soars.

Fluid fabrication flips the model. AI continuously senses, predicts, and adjusts:

- Machines optimize their own performance

- Processes adjust dynamically to supply and demand

- Quality checks happen autonomously

- Waste becomes trackable and avoidable

This is adaptability in motion production that flows like a living system.

How AI-Enhanced Production in Sustainable Manufacturing Works

AI has evolved beyond performing repetitive tasks. Today, it orchestrates entire production ecosystems from sourcing to recycling:

Intelligent resource planning

Real-time quality assurance

Predictive maintenance with early fault detection

Optimized energy and emission management

Support for circular economy workflows

Every stage benefit from insights that improve both environmental and business outcomes.

Predictive Intelligence for Greener Operations

One of the biggest sustainability breakthroughs is predictive analytics. AI systems analyze thousands of data points about temperature, vibrations, and consumption patterns to foresee failures before they disrupt production. By preventing breakdowns, manufacturers avoid costly downtime and reduce the carbon footprint associated with emergency repairs, scrap waste, and replacement parts.

With prescriptive AI, automation goes a step further:

Not just predicting what will happen but recommending or executing the best response to keep operations efficient and eco-friendly.

Digital Twins: Designing Without Waste

A Digital Twin a virtual clone of a physical asset or production line helps engineers test ideas without risking materials, safety, or downtime.

They can simulate:

- Energy variations

- Layout changes

- New materials

- Production speed adjustments

This enables decision-making that is smarter and more sustainable, before anything changes in the real factory.

Zero trial-and-error waste. Zero unnecessary consumption. Maximum innovation.

Autonomous Material Movement

Smart robotics and AI-controlled transport systems ensure the right materials reach the right place at the right time with minimal energy usage.

No manual misrouting.

No excessive conveyor run-time.

No idle energy consumption.

Human workers can focus on high-value roles while automation handles precision logistics.

AI-Driven Circular Manufacturing

Sustainability doesn’t end at the product sale. AI helps manufacturers plan for material return, reuse, reprocessing, and remanufacturing, evolving toward a true circular economy.

- Smarter recycling paths

- Automated component grading

- Traceability of material footprint

- Longer product lifecycles

Every gram of resource gains renewed purpose.

Human-Centered Technology

Despite all the automation, people are still in the heart of manufacturing. AI assists human workers with:

- Safety predictions in hazardous zones

- On-the-job learning through augmented insights

- Reduced cognitive load by handling complex data analysis

Humans lead. AI enhances. Machines are executed.

That’s the balance of a future-ready workforce

Real-World Execution: Already Transforming Industries

Across sectors automotive, electronics, pharma, food processing manufacturers are witnessing:

20–40% reduction in energy consumption

30–60% improvement in overall equipment efficiency

Fewer rejects and improved lifecycle sustainability

Faster compliance with environmental standards and ESG goals

This proves that sustainability is not a trade-off, it’s a smart business strategy.

The Future of Fluid Fabrication

As edge AI, hydrogen-based power, autonomous factories, and quantum computing evolve, tomorrow’s manufacturing systems will:

- Operate with near-zero downtime

- Achieve real-time carbon accountability

- Enable rapid sustainable product innovation

- Transition fully to produce-reuse-recover ecosystems

AI-Enhanced Production in Sustainable Manufacturing is rewriting the blueprint of industrial progress, turning responsibility into profitability.

Conclusion

We have entered a new chapter where manufacturing doesn’t just make products, it protects the planet while doing it. Fluid fabrication represents agility, intelligence, and sustainability working together. With AI-Enhanced Production in Sustainable Manufacturing, industries are proving that greener operations can also be faster, smarter, and more profitable.

The question is no longer “Should we adopt AI for sustainability?”

It’s “How fast can we get there?”