In today’s competitive landscape, the manufacturing sector stands on the brink of a revolutionary transformation. The traditional factories of the past are giving way to smart, adaptive, and interconnected systems-ushered in by Industry 4.0. Often called the Fourth Industrial Revolution, Industry 4.0 blends advanced technologies like the Internet of Things (IoT), Artificial Intelligence (AI), Big Data, Cloud Computing, and Cyber-Physical Systems to build the Factory of the Future. But what exactly does that mean, and how can businesses practically embrace it?

What is Industry 4.0?

Industry 4.0 refers to the digital transformation of manufacturing and related industries through smart technologies. It follows previous industrial revolutions-mechanization, mass production, and automation-but with a key difference: integration of digital intelligence and real-time data across every layer of operations.

It’s not just about automation. It’s about intelligent automation, where machines don’t just act but learn, adapt, and evolve.

Key Pillars of the Future Factory

To envision and build the factory of the future, it’s important to understand the foundational technologies and principles driving it.

- Smart Machines and IoT

At the heart of Industry 4.0 is a network of smart, sensor-equipped machines that communicate with each other. These IoT-enabled devices collect real-time data-from machine temperature and vibration to production metrics-and share it across platforms.

Example: A CNC machine detects excessive vibration, signals predictive maintenance software, and automatically schedules downtime to avoid failure.

- Cyber-Physical Systems (CPS)

CPS are integrations of computation, networking, and physical processes. They create a seamless link between the digital and physical worlds, allowing real-time monitoring, remote control, and even autonomous decision-making.

Impact: Machines become more than tools-they become collaborators in production processes.

- Cloud Computing and Edge Processing

Cloud platforms allow scalable data storage and analysis, while edge computing handles data locally for real-time decisions. In a future-ready factory, this hybrid approach ensures low latency and high processing power.

Benefit: Quicker insights, reduced downtime, and better resource allocation.

- AI and Machine Learning

AI takes the vast data collected by IoT sensors and finds patterns humans can’t. It powers predictive maintenance, quality control, supply chain optimization, and even production planning.

Use case: AI algorithms analyze product defects in real-time and fine-tune the production parameters to maintain quality without human intervention.

- Digital Twins

A digital twin is a virtual replica of a physical asset or process. It allows real-time simulation, testing, and forecasting without interrupting actual operations.

Real-world impact: Engineers can simulate a new production line configuration digitally, spot bottlenecks, and optimize flow before physically implementing it.

Benefits of Building a Factory of the Future

Increased Efficiency and Productivity

With machines monitoring themselves and systems making data-driven decisions, production cycles shorten, and waste is minimized.

Predictive Maintenance

Sensors detect early warning signs of failure, allowing scheduled maintenance-cutting unexpected downtimes and saving costs.

Real-Time Visibility

Digital dashboards offer real-time insights into every aspect of the production line, from supply chains to output rates, enabling quicker decisions and agile responses.

Mass Customization

With flexible, automated lines, manufacturers can offer personalized products at scale-fulfilling changing consumer demands without compromising efficiency.

Sustainable Manufacturing

Energy monitoring, waste reduction, and optimized resource use all support a greener, more sustainable manufacturing model.

Challenges to Consider

While the promise of Industry 4.0 is immense, companies must navigate several challenges:

- Legacy Systems Integration: Many older machines lack connectivity.

- Cybersecurity Risks: More connectivity means higher vulnerability.

- Skill Gaps: Workforce training in AI, data science, and automation is crucial.

- High Initial Costs: The ROI is substantial, but the upfront investment can be steep.

Roadmap to Transformation

- Start with a Pilot: Test smart technology on a single line or process.

- Invest in Infrastructure: Ensure connectivity, sensor capability, and data architecture.

- Train the Workforce: Upskill employees in digital literacy and tech-driven operations.

- Partner Strategically: Collaborate with technology providers, consultants, and startups.

- Scale with Agility: Expand successful pilots and refine based on data feedback.

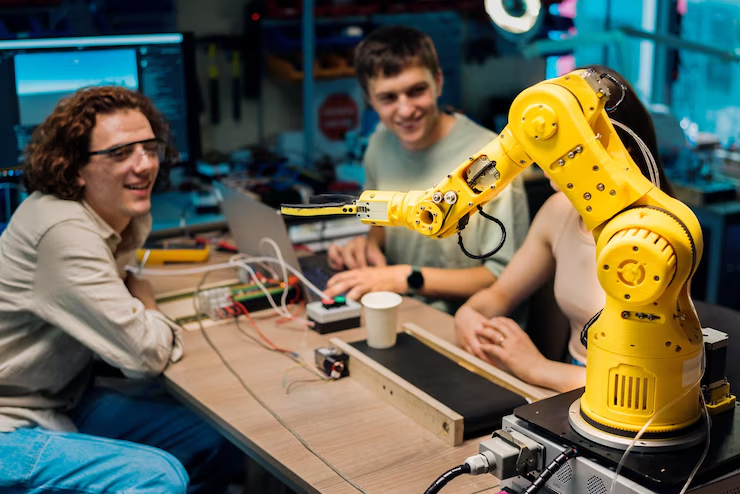

The Human Element: People + Machines

One of the biggest misconceptions is that Industry 4.0 replaces humans. In reality, it elevates human roles-from repetitive tasks to value-added functions like analysis, strategy, and innovation. Workers become decision-makers, empowered by real-time insights and digital tools.

Conclusion

The Factory of the Future isn’t a far-off concept-it’s already being built, one smart decision at a time. Industry 4.0 isn’t just a technological upgrade; it’s a strategic reinvention of how we manufacture, manage, and deliver. Businesses that embrace this shift stand to gain not just in productivity and profitability, but in resilience, sustainability, and relevance in a rapidly changing world.

The question isn’t if you’ll adopt Industry 4.0-but when and how effectively you’ll transform.