Discover how Intelligent Industry 4.0 transforms manufacturing with AI, IoT, digital twins, and smart automation to build efficient, sustainable factories. Intelligent Industry 4.0: Building a Smarter Future for Manufacturing The manufacturing world is entering a decisive new era with Intelligent Industry 4.0. This advanced approach goes beyond traditional Industry 4.0 by embedding artificial intelligence, data-driven...

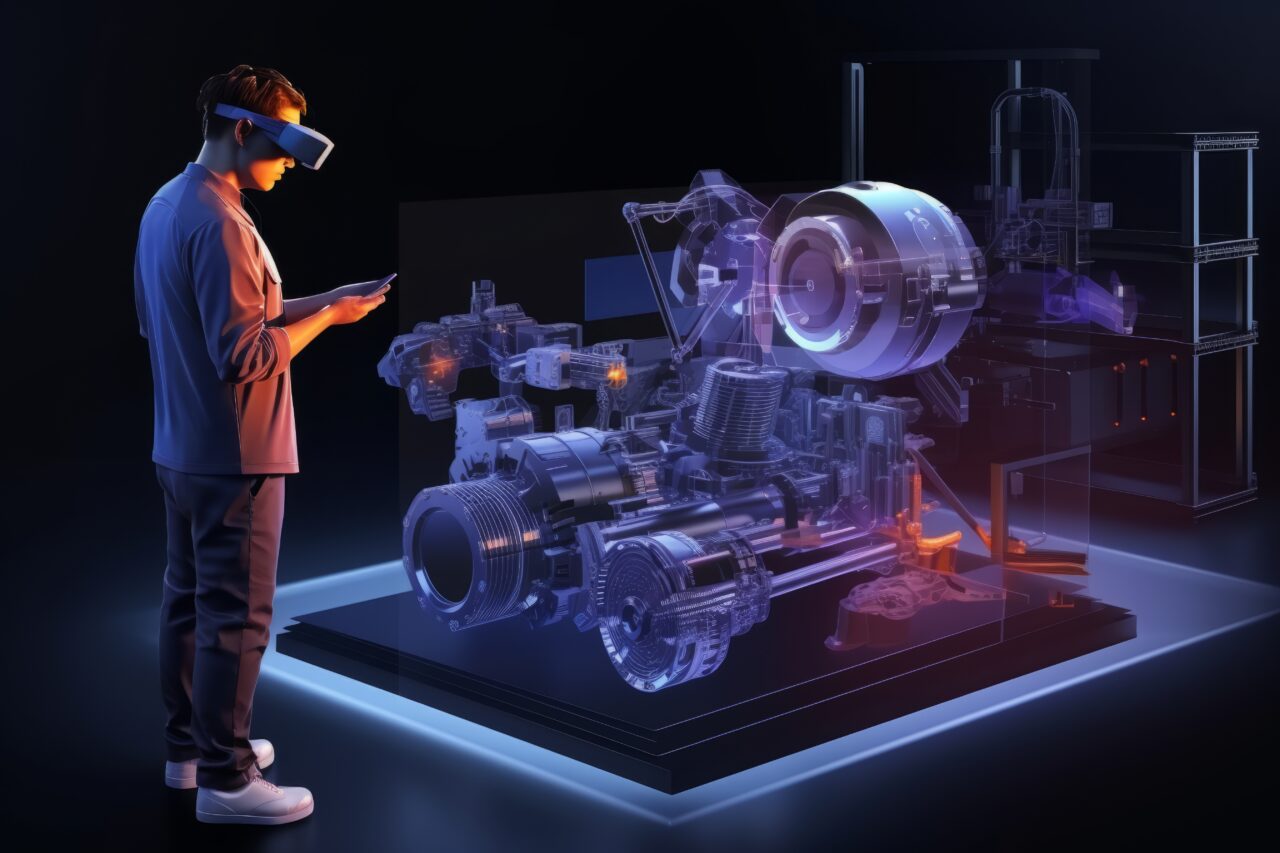

Digital Twins in Manufacturing – Creating a Virtual Mirror for Real-Time Decisions

Digital Twins in Manufacturing – Creating a Virtual Mirror for Real-Time Decisions. Imagine being able to predict a machine failure before it happens, simulate a new factory layout without moving a single piece of equipment, or optimize production performance from thousands of miles away-all without touching the physical plant. Welcome to the world of Digital...

How AI and IoT Are Driving Hyper – Automation in Manufacturing

The manufacturing world is undergoing a historic shift—from automated to hyper-automated. In this transformation, the convergence of Artificial Intelligence (AI) and the Internet of Things (IoT) is playing a defining role. Machines are no longer just automated—they’re intelligent, self-optimizing, and capable of making real-time decisions. This new frontier is called hyper-automation, and it’s rapidly redefining...

The Role of Cyber-Physical Systems in Smart Manufacturing

In the era of Industry 4.0, manufacturing is no longer just about machines, labor, and materials-it’s about intelligent systems that blend the physical and digital worlds. At the core of this transformation lies the Cyber-Physical System (CPS), a powerful concept driving the emergence of smart manufacturing. CPS connects machines, computing, and real-time data to create...

Machine Learning for Predictive Equipment Maintenance in Industrial Settings

Machine Learning for Predictive Equipment Maintenance in Industrial Settings. Three months ago, I stood in a steel mill watching a maintenance team disassemble a massive rolling machine that had failed without warning. Production had stopped completely. Workers stood idle. The plant manager estimated the cost at ₹15 lakh per hour of downtime, and they were...

From Sensors to Strategy – Turning IoT Data into Actionable Manufacturing Intelligence

From Sensors to Strategy – Turning IoT Data into Actionable Manufacturing Intelligence. Last month, I walked through a manufacturing plant in Pune that looked nothing like the noisy, chaotic factories I remembered from my engineering college days. This one was almost eerily quiet, with screens displaying colorful dashboards at every workstation. When a particular machine...

Edge Computing in Industrial Settings – Processing Data Where It’s Created

Edge Computing in Industrial Settings – Processing Data Where It’s Created. I was standing on the factory floor of a major automotive plant outside Chennai last month when something remarkable happened. A robotic arm suddenly adjusted its movement pattern without any human intervention. The plant manager noticed my surprise and explained, “That’s edge computing in...

Digital Twins in Manufacturing – Creating Virtual Replicas for Real-World Optimization

Digital Twins in Manufacturing – Creating Virtual Replicas for Real-World Optimization. I remember the first time I saw a digital twin in action at a manufacturing plant in Bangalore. What looked like a simple 3D model on a screen was actually a living, breathing virtual replica of the entire assembly line, complete with real-time data...

Digital Transformation in Manufacturing – The Four Stages of Industry 4.0 Adoption

Digital Transformation in Manufacturing – The Four Stages of Industry 4.0 Adoption. Last month, I walked through a factory that had been operating since the 1970s. The contrast was striking ancient hydraulic presses stood next to collaborative robots, legacy control systems operated alongside AI-powered quality inspection cameras. The plant manager pointed to a machine where...

Automation vs Augmentation – How AI is Transforming Manufacturing Workforces

Last week, I visited a bearing manufacturing plant outside Pune where two striking scenes unfolded side by side. In one section, robotic arms performed precision welding with superhuman consistency, no humans in sight. In the adjacent bay, technicians wearing AR headsets worked alongside collaborative robots, their movements synchronized in a choreographed dance of production. Same...