Discover how Intelligent Industry 4.0 transforms manufacturing with AI, IoT, digital twins, and smart automation to build efficient, sustainable factories.

Intelligent Industry 4.0: Building a Smarter Future for Manufacturing

The manufacturing world is entering a decisive new era with Intelligent Industry 4.0. This advanced approach goes beyond traditional Industry 4.0 by embedding artificial intelligence, data-driven insights, and digital twins into the core of industrial operations.

As manufacturers face global competition, volatile supply chains, and stricter sustainability targets, Intelligent Industry 4.0 is enabling smarter, faster, and cleaner production.

Understanding Intelligent Industry 4.0

Unlike the earlier wave of automation, Intelligent Industry 4.0 integrates AI-powered decision-making, edge computing, and cyber-physical systems. Factories no longer just collect data; they learn from it in real time. This allows production environments to predict failures, adjust schedules, optimize energy use, and support human operators with data-backed insights.

Core Pillars of Intelligent Industry 4.0

- Smart IoT Connectivity

Industrial sensors and connected machines provide a continuous data stream on production performance, quality, and energy consumption. Intelligent platforms integrate this data to create a real-time view of factory operations.

- AI-Driven Predictive Analytics

Machine learning models turn raw industrial data into actionable intelligence. Manufacturers can anticipate equipment breakdowns, reduce downtime, and fine-tune production settings to increase yield and quality.

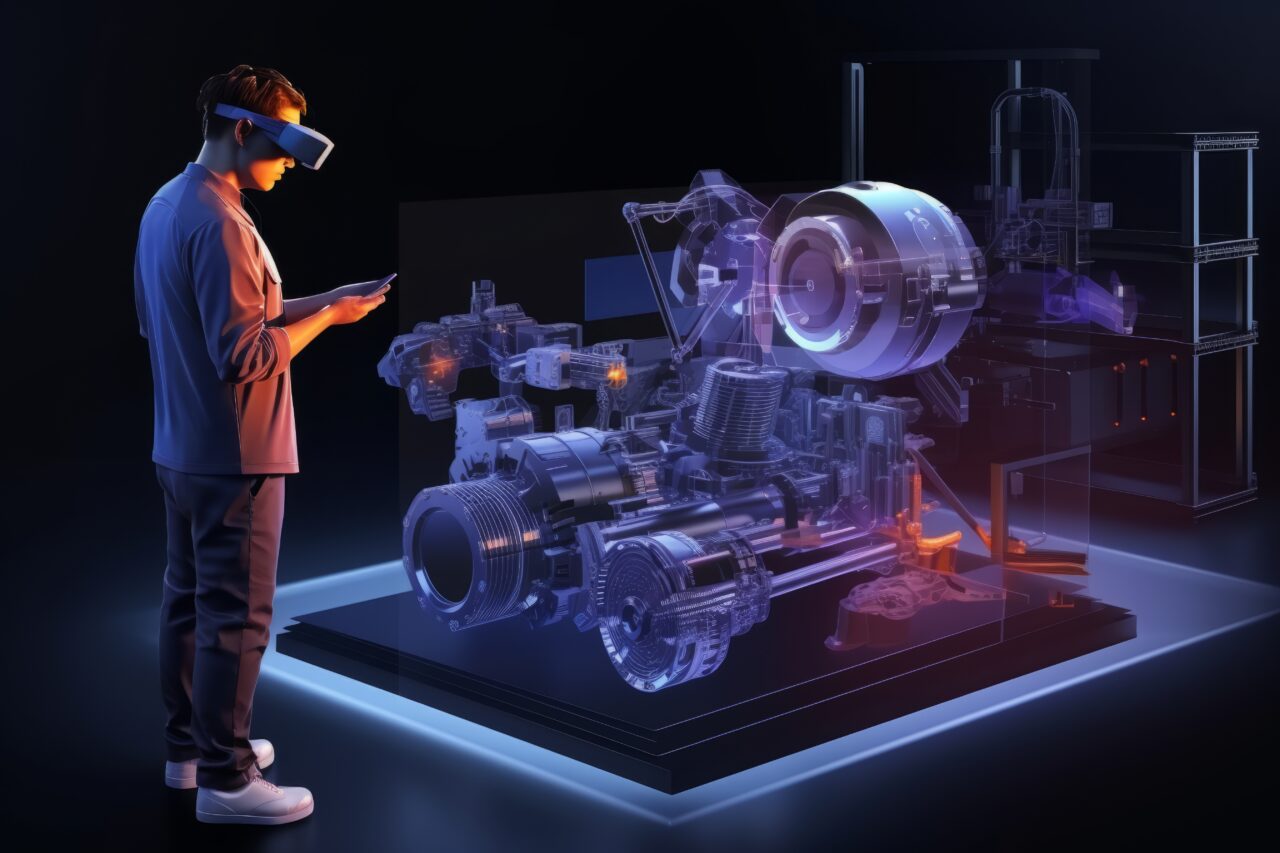

- Digital Twins for Process Optimization

By simulating machines, lines, and even full plants, digital twins help test scenarios and predict outcomes before changes occur in the physical world saving time, reducing waste, and accelerating innovation.

- Cyber-Physical Integration

Robotics, automated guided vehicles (AGVs), and collaborative cobots work with human operators in a seamless ecosystem. Intelligent Industry 4.0 ensures these elements communicate efficiently for smoother workflows and safer shop floors.

- Sustainability and Energy Efficiency

From tracking carbon emissions to optimizing HVAC and power usage, the approach supports ESG compliance and helps manufacturers reduce operational costs while meeting net-zero commitments.

How Intelligent Industry 4.0 Transforms Manufacturing

Manufacturers that adopt this approach experience transformation across the entire lifecycle:

- Design & Prototyping: Data-driven design accelerates innovation cycles and product customization.

- Operations: Predictive maintenance minimizes downtime and improves overall equipment effectiveness (OEE).

- Supply Chains: Demand-sensing algorithms enhance procurement agility and inventory management.

- Energy Use: Intelligent monitoring can cut energy bills by 15–25% while lowering emissions.

- Workforce Productivity: Operator dashboards and AR/VR-assisted training make teams faster and more precise.

Benefits of Embracing Intelligent Industry 4.0

- Increased Efficiency: AI-guided process improvements deliver up to 20% higher throughput.

- Reduced Costs: Predictive maintenance and energy optimization lower production costs by 10–15%.

- Improved Quality: Vision-based inspection and real-time feedback loops minimize defects.

- Greater Sustainability: Smart energy management contributes to long-term ESG goals.

- Faster Innovation: Digital twins and rapid testing reduce prototyping time by up to 50%.

Roadmap to Intelligent Industry 4.0 Adoption

- Assessment & Planning: Identify high-impact areas like critical equipment, energy hotspots, or key bottlenecks.

- Technology Enablement: Deploy IoT sensors, secure data pipelines, and hybrid edge-cloud platforms.

- Data & AI Integration: Use historical and live data to build predictive models and prescriptive workflows.

- Pilot & Scale: Start small such as a production line or energy optimization project then expand plant-wide.

- Continuous Improvement: Track KPIs and keep upgrading skills, governance, and AI models.

Why Intelligent Industry 4.0 Matters Now

Global manufacturers are under pressure to stay competitive, meet green regulations, and adapt to demand volatility. Intelligent Industry 4.0 delivers the tools to achieve all three goals simultaneously turning data into decisions, machines into collaborators, and factories into resilient, adaptive enterprises.

Conclusion: The Future Is Intelligent

By embedding intelligence into every layer sensors, analytics, automation, and workforce collaboration Intelligent Industry 4.0 is shaping a smarter and more sustainable future for manufacturing. Organizations that embrace it today will not only gain operational advantages but also secure their place in the next generation of industrial innovation.