Discover how Intelligent Industry 4.0 transforms manufacturing with AI, IoT, digital twins, and smart automation to build efficient, sustainable factories. Intelligent Industry 4.0: Building a Smarter Future for Manufacturing The manufacturing world is entering a decisive new era with Intelligent Industry 4.0. This advanced approach goes beyond traditional Industry 4.0 by embedding artificial intelligence, data-driven...

Building the Factory of the Future with Industry 4.0

In today’s competitive landscape, the manufacturing sector stands on the brink of a revolutionary transformation. The traditional factories of the past are giving way to smart, adaptive, and interconnected systems-ushered in by Industry 4.0. Often called the Fourth Industrial Revolution, Industry 4.0 blends advanced technologies like the Internet of Things (IoT), Artificial Intelligence (AI), Big...

From Sensors to Strategy – Turning IoT Data into Actionable Manufacturing Intelligence

From Sensors to Strategy – Turning IoT Data into Actionable Manufacturing Intelligence. Last month, I walked through a manufacturing plant in Pune that looked nothing like the noisy, chaotic factories I remembered from my engineering college days. This one was almost eerily quiet, with screens displaying colorful dashboards at every workstation. When a particular machine...

Digital Transformation in Manufacturing – The Four Stages of Industry 4.0 Adoption

Digital Transformation in Manufacturing – The Four Stages of Industry 4.0 Adoption. Last month, I walked through a factory that had been operating since the 1970s. The contrast was striking ancient hydraulic presses stood next to collaborative robots, legacy control systems operated alongside AI-powered quality inspection cameras. The plant manager pointed to a machine where...

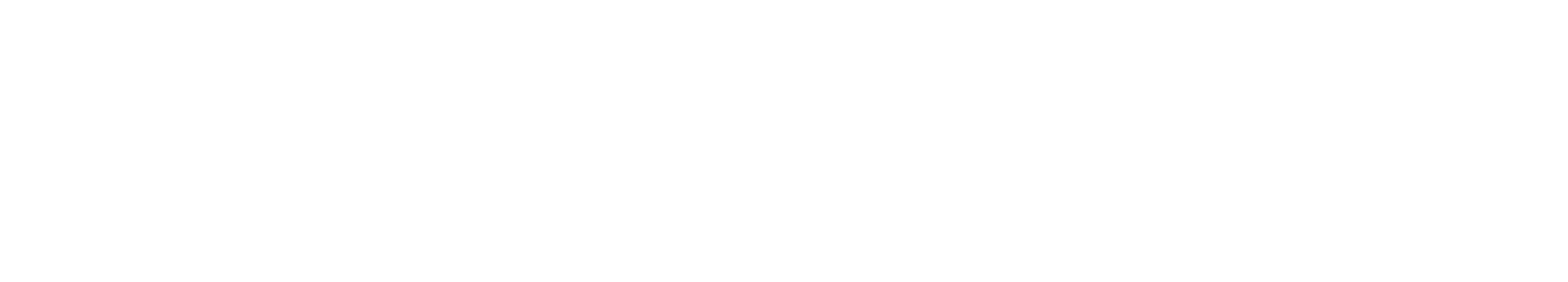

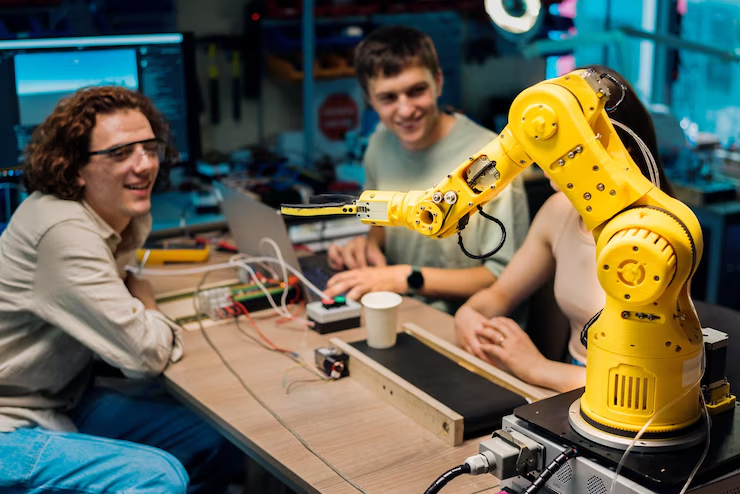

Automation vs Augmentation – How AI is Transforming Manufacturing Workforces

Last week, I visited a bearing manufacturing plant outside Pune where two striking scenes unfolded side by side. In one section, robotic arms performed precision welding with superhuman consistency, no humans in sight. In the adjacent bay, technicians wearing AR headsets worked alongside collaborative robots, their movements synchronized in a choreographed dance of production. Same...